Biodiesel from Algae Oil

Introduction

By Allison Vela-Mendoza

Algae are eukaryotes and conduct photosynthesis within membrane-bound organelles called chloroplasts. Chloroplasts contain circular DNA that is similar in structure to cyanobacteria. Algae are prominent in bodies of water, common in terrestrial environments.

Algal organisms are photosynthetic macro-algae or microalgae growing in aquatic environments. Macro-algae or “seaweeds” are multicellular plants growing in salt or fresh water. They are classified into three broad groups based on their pigmentation: brown seaweed (Phaeophyceae), red seaweed (Rhodophyceae) and green seaweed (Chlorophyceae).

Microalgae are unicellular photosynthetic microorganisms, living in saline or fresh water environments that convert sunlight, water and carbon dioxide to algal biomass. The three most important classes of microalgae in terms of abundance are the diatoms (Bacillariophyceae), the green algae (Chlorophyceae), and the golden algae (Chrysophyceae) (Demirbas & Demirbas, 2010).

Among the eukaryotic, green microalgae of the class Chlorophyceae, those most widely utilized belong to the genera Chlamydomonas, Chlorella, Haematococcus, and Dunaliella. As aquatic relatives of plants, microalgae flourish in aerated, liquid cultures where the cells have sufficient access to light, carbon dioxide, and other nutrients. Algae are primarily grown photoautotrophically; still, some species are able to survive heterotrophically by degrading organic substances like sugars. Unlike terrestrial plants, microalgae do not require fertile land or irrigation. Because algae consume carbon dioxide, large-scale cultivation can be used to remediate the combustion exhaust of power plants (Rosenberg et al., 2008).

Algae biomass can play an important role in solving the problem between the production of food and that of biofuels in the near future. Microalgae appear to be the only source of renewable biodiesel that is capable of meeting the global demand for transport fuels.

The potential of algae oil as a fuel source

Over 80% of the energy we use comes from three fossil fuels: petroleum, coal, and natural gas. About 98%of carbon emissions result from fossil fuel combustion. About 98% of carbon emissions result from fossil fuel combustion. Reducing the use of fossil fuels would significantly reduce the amount of carbon dioxide and other pollutants produced. This can be achieved by either using less energy altogether or by replacing fossil fuel by renewable fuels. Renewable energy is a promising alternative solution because it fixes CO2 in the atmosphere through photosynthesis. They also produce lower or negligible levels of greenhouse gases and other pollutants when compared with the fossil energy sources they replace.

Algae, like corn, soybeans, sugar cane, wood, and other plants, use photosynthesis to convert solar energy into chemical energy. They store this energy in the form of oils, carbohydrates, and proteins. The plant oil can be converted to biodiesel, which is why biodiesel is a form of solar energy. The more efficient a particular plant is at converting that solar energy into chemical energy, the better it is from a biodiesel perspective, and algae are among the most photosynthetically efficient plants on earth.

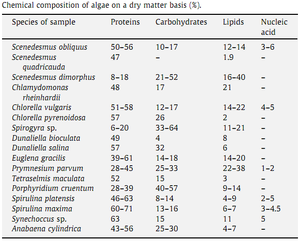

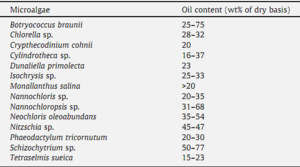

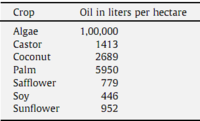

The annual productivity and oil content of algae is far greater than seed crops. Soybean can only produce about 450 l of oil per hectare. Canola can produce 1200 l per hectare, and palm can produce 6000 l. Algae, on the other hand, can yield 90,000 l per hectare (Table 3) (Demirbas & Demirbas, 2010). Microalgae contain lipids and fatty acids as membrane components, storage products, metabolites and sources of energy. Algae contain anywhere between 2% and 40% of lipids/oils by weight (Table 1). Algae can grow anywhere there is enough sunshine and some can grow in saline water. All algae contain proteins, carbohydrates, lipids and nucleic acids in varying proportions. Microalgae can complete an entire growth cycle every few days. Although the percentages may vary, there are types of algae that are comprised up to 40% of their overall fatty acids. The culture of algae can yield 30-50% oil (Table 2). Oil supply is based on claims that 47,000-308,000 l/hectare/year of oil could be produced using algae.

Highest-yielding algae

The algae used in biodiesel production are usually aquatic unicellular green algae (Chlorophyceae). This type of algae is a photosynthetic eukaryote characterized by high growth rates and high population densities. Under good conditions, green algae can double its biomass in less than 24 hours. Green algae can also have high lipid contents, usually over 50%. This high yield is ideal for intensive agriculture and can be an excellent source for biodiesel production (Demirbas & Demirbas, 2010).

Chlorella

Chlorella is a single-celled green algae belonging to the class of Chlorophyceae. It is a primary algae because it grows autotrophically. It is spherical in shape, about 2 to 10 μm in diameter, and does not have a flagella. Chlorella has green photosynthetic pigments, chlorophyll-a and chlorophyll-b, in its chloroplast. Using photosynthesis, it multiplies rapidly requiring only carbon dioxide, water, sunlight, and a small amount of minerals to reproduce. Chlorella is believed to be capable in serving as a potential food and energy source because of its photosynthetic efficiency to reach 8% comparable to other highly efficient crops such as sugar cane(Wikipedia-Chlorella).

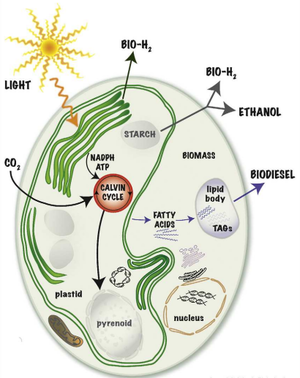

Manipulation of metabolic pathways can redirect cellular function toward the synthesis of preferred products and even increase the processing capabilities of microalgae (Figure 1). For heterotrophic microalgae, outside carbon sources offer a large amount chemical energy, which the cells often store as lipid droplets. Heterotrophically cultivated Chlorella protothecoides has been shown to accumulate as much as 55% of its dry weight as oil, compared to only 14% in cells grown photoautotrohpically (Rosenberg et al., 2008).

Dunaliella

Dunaliella is a unicellular green algae also belonging to the class of Chlorophyceae. It too is a primary algae. It is rod to oval shaped and about 9 to 11 μm in diameter. The organisms are simple to cultivate and do not clump or form chains.

The properties of various fatty esters determine the overall fuel properties of the biodiesel fuel. There is no one strain or species of algae that can be said to be the best in terms of oil yield for biodiesel. But, diatoms along with green algae are the most promising. Scenedesmus dimorphus is a unicellular algae in the class Chlorophyceae (green algae). While this is one preferred species for oil yield for biodiesel, one of the problems with Scenedesmus is that it is heavy, and forms thick sediments if not kept in constant agitation. Dunaliella tertiolecta is a marine green flagellate with a size of 10 to 12 μm in diameter. This strain is said to have an oil yield of about 37%. D. tertiolecta is a fast growing strain, therefore allowing it to have a high carbon dioxide rate (Wikipedia-Dunaliella).

Processes converting algae oil to biodiesel

Photosynthesis is the first step in the conversion of light to chemical energy and ultimately responsible for supporting all biofuel synthetic processes, converting solar energy into biomass, carbon storage products (carbohydrates and lipids) and hydrogen (Figure 4) (Beer et al., 2009).

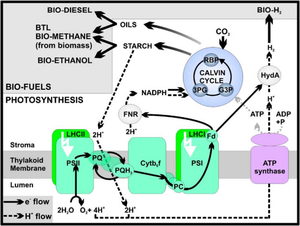

In green algae, light is captured by light harvesting complex proteins, referred to as LHCI and LHCII (Figure 5). Their expression is dependent on environment conditions (light intensity). These proteins bind a large amount of the chlorophyll and carotenoids in the plant and play a role in both light capture and in the dissipation of excess energy, which would otherwise inhibit the photosynthetic reaction centers (photosystem II). Excitation energy used to drive the photosynthetic reactions is funneled to the photosynthetic reaction centers of photosystem I (PSI) and photosystem II (PSII) via the network of pigments bound by the LHC, PSII, and PSI subunits. In the beginning, PSII uses this energy to drive the photosynthetic water splitting reaction, which converts water into protons, electrons and oxygen. The electrons are passed along the photosynthetic electron transport chain via plastoquinone (PQ), cytochrome b6f (Cyt b6f), PSI, and ferredoxin (Fd) and on to NADPH. At the same time, protons are released into the thylakoid lumen by PSII and the PQ/PQH2 cycle. This generates a proton gradient, which drives ATP production via ATP synthase. The protons and electrons are recombined by ferredoxin-NADP+ oxidoreductase (FNR) to produce NADPH. NADPH and ATP are used in the Calvin cycle to produce the sugars, starch, oils that are required to produce bioethanol, biodiesel, and biomethane.

The Calvin cycle is an integral part of the photosynthetic process and responsible for fixing CO2 in a diverse range of organisms including primitive algae through to higher plants. The process uses ATP and NADPH generated by the light reactions (Schenk et al., 2008).

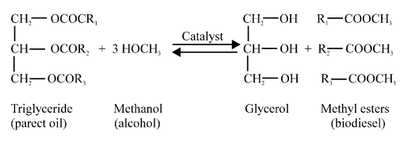

Algal oil is converted into biodiesel through a transesterification process. Oil extracted from the algae is mixed with alcohol and an acid or a base to produce the fatty acid methylesters that makes up the biodiesel. An excess of methanol is used to force the reaction to favor the right side of the equation. The excess methanol is later recovered and reused (Demirbas & Demirbas, 2010). If biomass is grown in a sustained way, its combustion has no impact on the CO2 balance in the atmosphere, because the CO2 emitted by the burning of biomass is offset by the CO2 fixed by photosynthesis.

The process of producing microalgal oil consists of producing microalgal biomass that requires light, carbon dioxide, water and inorganic nutrients (nitrates, phosphates, and iron). About half of the dry weight of microalgal biomass is carbon, which is usually derived from carbon dioxide. Therefore, producing 100 tons of algal biomass fixes roughly 183 tons of carbon dioxide. Optimal temperature for growing many microalgae is between 293 and 303 K. A temperature outside this range could kill or damage the cells.

Expeller/Press, solvent extraction with hexane, and supercritical fluid extraction are well-known methods to extract oil from algae. A press/expeller extracts 70-75% of the oils out of algae. Using chemicals like Hexane (which are relatively inexpensive) can also be used to extract algal oils. Supercritical fluid extraction is more efficient than solvent separation methods. Because supercritical fluids are selective, they provide high purity and product concentrations and can extract nearly 100% of the oils. In the supercritical fluid (CO2) extraction, CO2 is liquefied under pressure and heated to the point that it has the properties of both a liquid and gas. This liquefied fluid then acts as the solvent in extracting the oil. After oil extraction from algae, the remaining biomass fraction can be used as a high protein feed for livestock. This gives further value to the process and reduces waste.

Industrial reactors

Most of algal species are phototrophs and therefore require light for their growth. The phototropic microalgae are commonly grown in open ponds and photobioreactors. Open pond systems are shallow ponds in which algae are also cultivated. The open pond cultures are economically more favorable, but raise the issues of land cost, water availability, and appropriate climatic conditions. Photobioreactors are different types of tanks or closed systems in which algae are cultivated. Photobioreactors offer a closed culture environment, which is protected from invading microorganisms. This technology is relatively expensive compared to the open ponds because of the infrastructure costs. However, closed systems require less light and agriculture land to grow the algae. High oil species of microalgae cultured in growth-optimized conditions of photobioreactors have the potential to yield 19,000-57,000 l of microalgal oil per acre per year. An ideal biomass productions system should use the freely available sunlight (Demirbas & Demirbas, 2010).

Open pond systems

Open ponds have a variety of shapes and sizes but the most commonly used design is the raceway pond. An area is divided into a rectangular grid, with each rectangle containing a channel in the shape of an oval; a paddle wheel is sued to drive water flow continuously around the circuit. Raceway ponds are more expensive construct due to the extra infrastructure required (paddle wheel) and the faster flow rates mean more stable structures are required to ensure that the pond integrity is maintained (Figure 7). Open ponds are easy to maintain since they have large open access to clean off the biofilm that builds up on surfaces. The disadvantage of open systems is that by being open to the atmosphere, they lose water by evaporation at a rate similar to land crops and are also susceptible to contamination by unwanted species. Over time undesired species will inevitably be introduced and can reduce yields and even outcompete the desired algal culture (Schenk et al., 2008).

Photobioreactors

The most cost-effective way to farm microalgae is in large, circulating ponds. Closed photobioreactors provide sterility and allow for much greater control over culture parameters such as light intensity, carbon dioxide, nutrient levels, and temperature. Under optimal conditions, microalgal populations are capable of doubling within hours and achieving high cell densities (Rosenberg et al., 2008). Besides saving water, energy and chemicals, closed bioreactors have many other advantages, which are increasingly making them the reactor of choice for biofuel production, as their costs are reduced (Figure 8). They support up to fivefold higher productivity with respect to reactor volume and therefore have a smaller “footprint” on a yield basis. This is optimal because the goal is to collect as much solar energy as possible from a given piece of land. Most closed photobioreactors are designed as tubular reactors, plate reactors, or bubble column reactors. To increase efficiency, photobioreactors have to be designed to distribute light over a large surface area in order to provide moderate light intensities for the cells (light dilution). This is usually achieved by arranging tubular reactors in a fence-like construction. The fences are oriented in a north/south direction to prevent direct bright light hitting the surface. In this way sunlight is diluted in a horizontal and vertical direction (Schenk et al., 2008). A tubular photobioreactor consists of an array of straight transparent tubes that are usually made of plastic or glass (Figure 9). This tubular array, or the solar collector, captures the sunlight for photosynthesis. The solar collector tubes are generally less than 0.1 m in diameter to enable the light to penetrate into a significant volume of the suspended cells. The ground beneath the solar collector is either painted white or covered with white sheets of plastic to increase reflectance, which will increase the total light received by the tubes. (Christi, 2007).

For large-scale microalgae biofuel production there would need to be a series of photobioreactors of increasing size. As the bioreactors increase in size, the level of complexity should be reduce to minimize the cost per square meter. It is important to use an algal species that is both, fast growing during the inoculum scale-up stage and highly productive in the final open pond stage. This process allows for low nutrient conditions to avoid the dominance of invading species while encouraging the continuous production of algal biofuels (Schenk et al., 2008).

Economics of algae biodiesel production

Photobioreactors require 10 times capital investment than open pond systems. The estimated algal production cost for open pond systems ($10/kg) and photobioreactors ($30-$70/kg) is two order magnitudes higher than conventional agricultural biomass respectively. Assuming that biomass contains 30% oil by weight and carbon dioxide available at no cost, estimated production cost for photobioreactors and ponds would be $1.40 and $1.81 per liter of oil respectively. However, for microalgal biodiesel to be competitive with petrodiesel, algal oil price should be les than $0.48/L. It has been estimated that 0.53 billion m3 of biodiesel would be needed to replace current US transportation consumption of all petroleum fuels. The per unit area yield of oil from algae is estimated to be from 18,927 to 75,708 l per acre, per year; this is 7-31 times greater than the next best crop, palm oil (Demirbas & Demirbas).

To produce this quantity (0.53 billion) of biodiesel, palm oil would need to be grown over an area about 111 million (M) hectares. This is nearly 61% of all agricultural cropping land in the United States. Growing palm oil at this scale would be unrealistic because insufficient land would be left for producing food and other crops (Christi, 2007).

Reasons why algae biomass cultivation has potential

Biodiesel is currently produced from oil synthesized by conventional fuel crops that harvest the sun’s energy and store it as chemical energy. This presents a route for renewable and carbon-neutral fuel production.

Advantages of microalgal systems

Microalgal systems: 1) have a higher photon conversion efficiency (as evidenced by increased biomass yields per hectare), 2) can be harvested batch-wise nearly all-year-round, providing a reliable and continuous supply of oil, 3) can utilize salt and waste water streams, thereby reducing freshwater use, 4) can couple CO2-neutral fuel production with CO2 sequestration, 5) produce non-toxic and highly biodegradable biofuels (Schenk et al., 2008).

Advantages of biodiesel from algae oil

Algae oil/algae biofuel: 1) provides rapid growth rates, 2) grows practically anywhere, a high per-acre yield (7-31 times greater than the next best crop—palm oil), 3) algae biofuel is non-toxic, 4) algae biofuel is highly bio-degradable, 5) high levels of polyunsaturates in algae biodiesel is suitable for cold weather climates, 6) can reduce carbon emissions based on where it’s grown, 7) algae biomass can be produced at high volumes and this biomass can yield a higher percentage of oil than other sources, 8) algae oil has limited market competition, 9) algae can be cultivated on land, fresh water, or seawater, and 10) innovations of algae production allow it to become more productive while consuming resources that would otherwise be considered waste, 11)have a higher photon conversion efficiency, 12) can be harvested batch-wise nearly all-year-round, providing a reliable and continuous supply of oil, 13) and can utilize salt and waste water streams, thereby greatly reducing freshwater use (Schenk et al., 2008).

Algae have the potential of growing in places away from the farmlands and forests, thus minimizing the damages to the ecosystem and food chain supply. Algae can also be grown in sewage and next to power-plant smokestacks, where they can digest the pollutants and deliver the oil (Vijayaraghavan & Hemanathan, 2009).

Disadvantages of biodiesel from algae oil

Biodiesel from algae oil: 1) produces unstable biodiesel with many polyunsaturates, 2) biodiesel performs poorly compared to its mainstream alternative, and 3) it is relative new technology. Other limitations include the low concentrations of free CO2 that are required for peak algal growth and that algal grazers are a significant, but somewhat ignored problem (Schenk et al., 2008).

Challenges in Agriculture: 1) too much direct sunlight can kill algae, 2) temperature must be constant, 3) overcrowding will inhibit algae growth, 4) the “waste” oxygen they produce must be continually removed from the water, 5) open algal ponds are subject to evaporation and rainfall, which causes salinity and pH imbalances, 6) and local species of algae often overgrow the desired strain.

The difficulties in efficient biodiesel production from algae are not from the extraction of the oil, but in finding an algal strain with a high lipid content and fast growth rate that is not too difficult to harvest, and a cost-effective cultivation system (type of photobioreactor) that is best suited to that strain (Demirbas & Demirbas, 2010). New materials and designs for cultivation in closed bioreactors and the use of cutting-edge metabolic engineering and screening/selection techniques are thought to provide the biggest promises (Schenk et al., 2008).

Conclusion

Biodiesel derived from oil crops is a potential renewable and carbon neutral alternative to petroleum fuels. However, the high cost and limited supply of renewable oils prevent it from becoming a top competitor for petroleum fuels. As petroleum fuels cost rise and supplies decrease, biodiesel will become more attractive to both investors and consumers. Because biodiesel from oil crops, waste cooking oil and animal fat cannot fulfill a small fraction of the existing demand for transport fuels, microalgae appear to be the only source of renewable biodiesel that is capable of meeting the global demand for transport fuels.

According to U.S. Department of Energy, current research into efficient algal oil production is being done in the private sector, but if predictions from small scale production experiments show promise then using algae to produce biodiesel may be the only viable method by which to produce enough automotive fuel to replace current world gasoline usage

.

Currently, a large group of early-stage companies working on algae want to produce Algae oils for biodiesel production, replacing a significant proportion of the diesel fuel that currently serves about one-third of transport needs in the United States. Some commercial interests into large-scale algal-cultivation systems are looking to tie into existing infrastructures, such as coal-fired power plants or sewage treatment facilities. This approach provides the raw materials for the system, such as CO2 and nutrients, and also changes those wastes into resources ([4]).

References

“Chlorella.” Wikipedia, 23 April 2011. http://en.wikipedia.org/wiki/Chlorella

“Dunaliella.” Wikipedia, 23 April 2011. http://en.wikipedia.org/wiki/Dunaliella

“The Life Cycle of Liquid Fuels.” EV World. http://www.evworld.com/ARTICLE.CFM?STORYID=1558

“Tubular Photobioreactors.” Oilgae. 23 April 2011. http://www.oilgae.com/algae/cult/pbr/typ/tub/tub.html

“Cultivation of Algae in Open Ponds.” Oilgae. 23 April 2011. http://www.oilgae.com/algae/cult/op/op.html

“How Algae Biodiesel Works.” How Stuff Works. 23 April 2011. http://science.howstuffworks.com/environmental/green-science/algae-biodiesel3.htm

“Biodiesel from Algae oil.” Mora Associates. 11 May 2011. http://www.fao.org/uploads/media/0707_Wagner_-_Biodiesel_from_algae_oil.pdf

Edited by student of Joan Slonczewski for BIOL 238 Microbiology, 2011, Kenyon College.