Microbes in Food Production and Benefits Provided.

Introduction

Fermentation of bacterium and yeasts was originally used as a method of preservation but has been more developed and understood since then (Stahl 2008). These processes are now exploited in order to alter the texture and flavor of foods as well as to incorporate substances, which are beneficial to the health of consumers (Stahl 2008). Examples of the use of these microorganisms can be seen in products including cheeses, yogurt, kombucha and bread products.

Cheese

The production of cheese utilizes starter cultures being added to milk with the aim of producing semi-hard and hard cheeses (Marilley et al. 2004). The starter cultures produce lactic acid, resulting in a pH decrease in the milk and promoting curd synthesis (Stanton et al. 1998). Also, galactose and glucose are formed upon the hydrolysis of lactose by said cultures, and glucose is subsequently oxidized to pyruvate while galactose is converted to glucose-6-P and glyceraldehyde-3-P (Marilley et al. 2004). These molecules can be broken down further to short-chain compounds including diacetyl, acetate, and ethanol, which provide cheeses with their characteristic flavors (Marilley et al. 2004).

The microbes impact the flavor, smell, and texture of cheeses by their production of enzymes and molecules (Button et al. 2012). In Camembert cheese, spores of Penicillium camemberti grows on the surface of the cheese, forming a rind and secretes proteases into the cheese (Button et al. 2012). These proteases lyse the underlying curd and degrade the casein, leading to the semi-soft texture of Camembert (Button et al. 2012). A microaerophillic fungus, Penicillium roqueforti, is important in the making of blue cheese as it grows in crevices created in the cheese, and produces lipases which convert the fats in the cheese to fatty acids and methyl ketone 2-heptone, leading to the aroma characteristic of blue cheese (Button et al. 2012). An alternate example of the diversity of cheese by microbes is the holes in Swiss cheese, due to the fermentation by Propionibacterium freundenreichii Propionibacterium and the products of this fermentation, propionic acid and CO2, which forms the bubbles (Button et al. 2012). More information on Penicillium sp.: Penicillium

In order for these microbes to flourish and give the desired results, a number of factors must be controlled in this process (Beresford et al. 2001). These factors in include ensuring that moisture levels are not too low (promoting dehydration) or too high (increasing spoilage susceptibility) as these values can vary within different zones of the cheese, as well as salt content, and temperature (Beresford et al. 2001).

Yogurt

Yogurt is also a fermented milk product, which takes advantage of lactic acid generating bacteria cultures Lactobacillus and their use of lactose in milk as a substrate to produce lactic acid (Lourens-Hattingh et al. 2001). The enzymes “rennet” used in cheese production are not used in yogurt and the thickness of yogurt is due to the solubility of casein in the acid produced and added starch, pectin, and gelatin (Drake et al. 2000). Recently, live strains of Lactobacillus acidophilus and Bifidobacterium (AB-cultures) have been added to yogurt alongside S. thermophiles and L. bulgaricus (Lourens-Hattingh et al. 2001). These AB-cultures, referred to as “probiotics”, have been shown to provide benefit to the consumer by displacing toxin-producing bacteria from the gastrointestinal tract (Lourens-Hattingh et al. 2001).

Kombucha

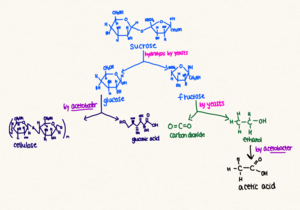

Like probiotics in yogurt, the beverage Kombucha, now consumed worldwide, also provides benefits upon consumption. These benefits are provided by inhibiting growth of undesirable microbes (Sreeramulu et al. 2000). The drink, which originated in China, includes acetic acid producing bacteria (Acetobacter xylinum, Acetobacter xylinoides, or Bacterium gluconicum) and yeasts along with sucrose, which liberates the glucose and fructose (Battikh et al. 2013). The fructose is metabolized to ethanol and carbon dioxide by yeasts, and the Acetobacter strains in Kombucha oxidize ethanol to produce acetic acid (Sreeramulu et al. 2000).

Investigations have shown that acetic acid and Kombucha show the same inhibition towards harmful bacteria including Escherichia coli, Salmonella enteritidis, Salmonella typhimurium, Heliobacter pylori, and Listeria monocytogenes Listeria moocytogenes in addition to other pathogenic microorganisms (Sreeramulu et al. 2000). Acetic acid inhibits growth by the mechanism of uncoupling; the uncharged acid molecules can permeate the cell membrane before dissociating in the interior and reducing the proton motive force, which organisms use to produce energy for their metabolic needs (Russell et al. 1998).

Bread

Yeasts Saccharomyces_cerevisiae have also been used to make bread, first occurring 12 000 years ago, by the Egyptians (Mondal et al. 2008). Now understood, it is established that yeast metabolize sugar in order to produce the fermentation products carbon dioxide and alcohol, which expand with temperature resulting in a risen bread dough. The alcohol is no longer present in the bread after baking is complete (Golden 1890). In addition to the yeast, sugar is added to initiate the fermentation and salt is incorporated to strengthen the gluten (Mondal et al. 2008). A good baking yeast should be able to tolerate diverse temperatures, acidity levels, presence of sugars and fats, as well as have the ability to utilize a variety of substrates (Linko et al. 1997).

Conclusion

The examples described above are only a few of the many uses of microorganisms in foods, which are now exploited to produce desired food products. Other uses include microbes to produce beers, wines, raisins, sauerkraut, pickles, and additional cheeses that weren’t previously discussed. In addition, more discoveries are continuously made and technology improvements are constantly designed, suggesting that the use of microbes in food production, and the benefits that come alongside their use, are not limited to what has been revealed to date.

References

Battikh H., Chaieb K., Bakhrouf A. and Ammar E. 2011. “Antibacterial and Antifungal Activities of Black and Green Kombucha Teas.” Journal of Food Biochemistry. 37(2013) pp. 231-236.

Beresford T.P., Fitzsimons N.A., Brennan N.L. and Cogan T.M. 2001. “Recent advances in cheese microbiology.” International Dairy Journal. 11(2001) pp. 259-274.

Button J.E. and Dutton R.J. 2012. “Cheese microbes.” Current Biology. 22(15) pp. R587-R589.

Drake M.A. and McKillip J. 2000. “Fermentation Microbiology: Making Cheese, Yogurt & Buttermilk as a Lab Exercise.” The American Biology Teacher. 62(1) pp. 65-67.

Golden K.E. 1890. “Fermentation of Bread.” Botanical Gazette. 15(8) pp. 204-209.

Linko Y., Javanainen P. and Linko S. 1997. “Biotechnology of bread baking.” Trends in Food Science & Technology. (8) pp. 339-344.

Lourens-Hattingh A. and Viljoen B.C. 2001. “Yogurt as probiotic carrier food.” International Dairy Journal. 11(2001) pp. 1-17.

Marilley L. and Casey M.G. 2003. “Flavours of cheese products: metabolic pathways, analytical tools and identification of producing strains.” International Journal of Food Microbiology. 90(2004) pp. 139-159.

Mondal A. and Datta A.K. 2007. “Bread baking – A review.” Journal of Food Engineering 86(2008) pp. 465-474.

Russell J.B. and Diez-Gonzalez, F. 1998. “The effects of fermentation acids on bacterial growth.” Advances in Microbial Physiology 1198(39) pp. 205-234.

Sreeramulu G., Zhu Y. and Knol W. 2000. “Kombucha Fermentation and Its Antimicrobial Activity.” Journal of Agriculture and Food Chemistry. (48) pp. 2589-2594.

Stanton C., Gardiner G., Lynch P.B., Collins J.K., Fitzgerald G. and Ross R.P. 1998. “Probiotic Cheese.” International Dairy Journal. 8(1998) pp. 491-496.

Stahl U. 2008. “Food biotechnology.” Springer.