Saccharomyces cerevisiae use and function in alcohol production

Introduction

By [David Torres]

At right is a sample image insertion. It works for any image uploaded anywhere to MicrobeWiki. The insertion code consists of:

Double brackets: [[

Filename: PHIL_1181_lores.jpg

Thumbnail status: |thumb|

Pixel size: |300px|

Placement on page: |right|

Legend/credit: Electron micrograph of the Ebola Zaire virus. This was the first photo ever taken of the virus, on 10/13/1976. By Dr. F.A. Murphy, now at U.C. Davis, then at the CDC.

Closed double brackets: ]]

Other examples:

Bold

Italic

Subscript: H2O

Superscript: Fe3+

Introduction

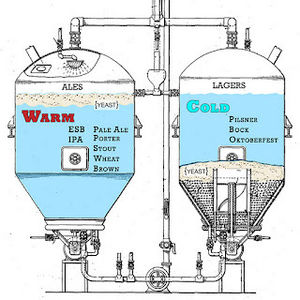

Saccharomyces cerevisiae is a species of yeast generally used in the beer and wine making process. This type of fungi has been studied as a eukaryotic model organism and was the first eukaryotic genome to be completely sequenced1.Many proteins and pathways were discovered in humans by studying the homologs found in the yeast. The yeast used in the beer making process ferments the different types of sugars found in the wort, pre-fermented beer, to produce ethanol. This species has been has been in use for thousands of years. It is believed beer technology was acquired from Germanic and Celtic tribes around the 1st century A.D. There was later the invention of lager beer technology in the 16th century2. However the oldest known example of yeast used in fermentation of a beverage was found in China and dates back 7000 B.C3. This species of yeast can be found all around the world on the surface of fruits and plants, in the soil, the gastrointestinal tract of animals, and the skin surface of animals. Today it is mainly found on the surface of equipment that is used in the fermentation of beer or in the cellars and barrels were the beer or wine is fermented. Saccharomyces cerevisiae is considered to a top–fermenting yeast because as the yeast flocculate or clump together they attach to the carbon dioxide being produced and float to the top of the wort. This allowed brewers to collect the yeast and create more colonies for later beers. The top-fermenting yeast is also characterized by the warm temperature required for optimal fermentation. This temperature ranges from 59 to 68 °F. The other types of yeast are bottom fermenting. The bottom-fermenting yeast was found to be a different strain called Saccharomyces pastorianus. This fermentation is characterized by a cooler temperature required, generally around 50 °F. The brewers would collect the yeast from the bottom of the fermentation chambers to culture and use in other beers. The bottom-fermenting yeast are what is used to make lager style beers while the top fermenting are used in the production of ales4.

The final type of yeast used in beer brewing is wild yeast. In this process the wort is exposed to wild yeast and bacteria that ferment the sugars. This process produces ethanol and waste products from both the yeast and the bacteria. The waste products of the bacteria give the beer a “funky” taste. This style of beer is known as being sour.

Ales and lagers are the two main categories of beer. Ale is described as being more hearty and robust along with very fruity notes. Where as lagers are considered to be smooth, crisp and clean. The majority of beers found on college campuses are of the lager variety. These include brands like Natural Ice, Keystone, and Pabst Blue Ribbon. There has been a recent surge of ales with the craft beer movement sweeping the United States. Some popular brands include Sierra Nevada, Dogfish head, and Samuel Adams.

Cell structure

Similar to other eukaryotes Saccharomyces cerevisiae has membrane bound organelles such as mitochondria, nucleus, and vacuoles. The 17 chromosomes it contains are stored in the nucleus. The majority of the metabolism processes occur in the mitochondria when there is oxygen present. The yeast can perform both aerobic and anaerobic respiration. Fermentation is performed in the cytoplasm when there is little to no oxygen present and an abundance of fermentable sugars. These sugars are converted into ethanol and carbon dioxide. The organelle that separates the yeast from other eukaryotes is the cell wall. The cell wall acts as both a defense against competing microbes and as a way for the cell to hold its shape. It is also responsible for the cells ability to survive in the seemingly toxic environment of high amount of ethanol. The cell wall is also of interest to researchers who believe that the cell wall is a potential target against fungi that cause infection5..

Reproduction

Saccharomyces cerevisiae is a unicellular eukaryote haploid containing 17 chromosomes. It can reproduce both sexually and asexually. The purpose of having both kinds of reproduction is to increase genetic diversity when the yeast mate. In the beer fermentation process the yeast generally undergo asexual budding and are found in the diploid state. This state is achieved when the two haploid cell types come together. These cell type are the a and α cells. The mating begins as both the a and α cells secrete a mating pheromone. The a cell secretes the a-factor and the α cell secretes the α-factor. These pheromones signal to the opposite cell type that it is near. The a cell produces a cell signaling receptor, Ste2, that binds the α-factor. In the same way the α cell produces Ste3, a receptor that binds the a-factor. When it is determined that a yeast cell of the opposite mating type is near the cell signaling receptors send a signal to the rest of the cell to begin growing a type of mating projection, known as a schmoo. The schmoo projection grows towards the opposite mating type cells pheromones. The cells eventually come together to form the diploid a/α cell. It is this diploid cell that can bud into a new daughter cell identical to the mother cell. However under stressful conditions such as lack of nutrients like sugars, carbons, and nitrogen the diploid cell can undergo sporulation. This sporulation allows the cell to survive while its haploid counterparts will die off. During the sporulation the cell undergoes meiosis where it creates four new progeny, two a cell types and two α cell type haploids. They are wrapped together in what is known as the ascus until enough nutrients are present to break it out of its dormant spore state6.

This entire lifecycle occurs during the fermentation stage of the brewing process. Specifically it can be broken down into four stages, the first being the lag stage where the main purpose is to build up reserves of energy. Yeast have internal glycogen reserves that it uses to begin reproducing. In this stage there is also a decrease in the overall pH of the wort because the yeast begin to take up the oxygen present. This oxygen is not used for aerobic respiration but for the biosynthesis of varying intermediates specifically those required for the membrane of the new daughter cells that will eventually bud off. The yeast have the capability to essentially shut off its aerobic respiration when there is an abundance of sugars present that it can ferment7. The next stage is the growth phase where the yeast begin to bud exponentially. The oxygen and glycogen that have been stored up are being used to create new yeast cells. It is not until the oxygen and the reserve sugars are depleted that the fermentation phase starts. In the fermentation phase the yeast stop replicating as much and begin to convert the simple sugars into ethanol, carbon dioxide, and other waste products that give the beer specific flavors. These products vary from yeast to yeast thus allowing for a wide variety of flavors in different styles of beer. The final phase is known as sedimentation. In this phase the yeast have begun to run out of sugars to ferment and nutrients to keep it alive. The sporulation process begins and the yeast can be seen clumping together and falling to the bottom of the beer into a dormant state. As it performs the sporulation the yeast also produces more glycogen as an energy reserve when they wake up from their dormant state to start the process over again8.

Brewing process

The brewing process consists of four main steps: the mashing, the boil, fermentation, and conditioning. The mashing is essential a steeping of the different grains and barley that will create both the flavor profile and the sugars necessary for the fermentation. The mashing involves pausing and starting the steep at varying temperatures. The different pauses at temperatures activate the enzymes to convert the starches in the grain and barley to fermentable sugars like glucose, fructose, and sucrose. This process can take anywhere from 1-2 hours and the end result is what is called a mash. The mash consists of the spent grains and barley that are free of starches and sugars. The water and sugar mixture is now called the wort. The wort next goes through the boiling process where hops are added as a bittering agent and to add aroma to the beer. The bittering hops are added to the wort at a rolling boil, an even and continuous boil, and left in the wort for anywhere from 45-90 minutes depending on the style of beer and how bitter the brewer desires the wort. The aroma hops are added near the end of the boil, anywhere from 15 minutes to flame out. The term flame out means when the heat source is stopped and the boil has stopped. The longer the aroma hops are in the wort the more of the floral, piney, or fruity smell is present in the beer. The aroma and bittering flavor depend on the types of hops used as well as the quantity. Following the boil the wort must be cooled down in order to add the yeast. If the wort is not cooled to approximately 68-78 °F the yeast will die if it comes into contact with the liquid. This will most likely result in no fermentation or off flavors if the beer does ferment with any surviving yeast. It is during the fermentation that the sugars in the wort are converted to alcohol; the wort can now be called beer. Most breweries conduct their fermentation in cylindroconical vessels(CCV). These vessels have a cylindrical top and cone bottom where the yeast collects. Some breweries use open fermentation vessels, which can expose the beer to infection, but make it easier to collect the yeast. The final necessary stage of beer brewing is the conditioning. This step matures the beer anywhere from 2 weeks to multiple years. The flavors in the beer meld together and the carbonation of the beer occurs in this step. The conditioning and carbonation can occur in a secondary container so as to not expose the beer to dead yeast that can give it off flavors from compounds like acetaldehydes.

Fermentation of alchohol

Saccharomyces cerevisiae is able to perform both aerobic and anaerobic respiration. The process begins with the yeast breaking down the different forms of sugar in the wort. The types of sugars typically found in wort are the monosaccharides glucose and fructose. These sugars contain a single hexose, which is composed of 6 carbon atoms in the molecular formula C6H12O6. Disaccharides are formed when two monosaccharides join together. Typical disaccharides in the wort are galactose, sucrose, and maltose. The third type of fermentable sugar in the wort is a trisaccharide. This trisaccharide is formed when three monosccharides join together. Maltotriose is the trisaccharide commonly found in the wort and is composed of three glucose molecules. The wort does contain other sugars such as dextrins but it is not fermentable by yeast10. These dextrins contain four monosaccarides joined together. In order for the yeast to use the disaccharides and trisaccharides they first must be broken down to monosaccharides. The yeast does this by using different enzymes both inside and outside the cell. The enzyme invertase is used to break down sucrose into glucose and fructose. The invertase catalyzes the hydrolysis of the sucrose by breaking the O-C (fructose bond)10. The other enzyme used is maltase, which breaks down maltose and maltotriose into glucose inside the cell. The enzyme does this by catalyzing the hydrolysis of the sugars by breaking the glycosidic bond holding the glucose molecules together.

Once the sugars are broken down into monosaccharides the yeast can use them. The primary step is called glycolysis. In this process the glucose is converted to pyruvate using different enzymes in a series of chemical modifications. The electrons from glucose end up being transferred to energy carrying molecules like NAD+ to form NADH. ATP is also formed when phosphates are transferred from high-energy intermediates of glycolysis to ADP. In the presence of oxygen aerobic respiration can occur. This occurs in the mitochondria of the yeast. The energy of the pyruvate is extracted when it goes through metabolic processes like the Krebs cycle. The products of this type of metabolism are ATP, H2O, and CO2. However if there is no oxygen present and an abundance of sugars, as in the wort, the yeast undergo alcoholic fermentation. This type of metabolism yields much smaller amounts of energy when compared to aerobic respiration. However, because of the large supply of sugars from the different grains the wort is a very good environment for fermentative growth. The alcoholic fermentation begins with the two pyruvate acquired from glycolysis. These two pyruvate are decarboxylated by pyruvate decarboxylase to form two acetaldehydes and CO2. The CO2 is the gas that is observed during fermentation as bubbles that float to the top of the wort creating the kräusen or beer head, the foam that is very characteristic of a freshly poured beer. Pyruvate decarboxylase is a homotetramer meaning it contains four identical subunits. This also means that is has four active sites. The active sites are where the pyruvate reacts with the cofactors thiamine pyrophosphate (TPP) and magnesium to remove the carbon dioxide9. The final step to form alcohol is the addition of a hydrogen ion to the aldehyde to form ethanol. This hydrogen ion is from the NADH made during glycolysis and converts back to NAD+. The ethanol is originally believed to serve as an antibiotic against other microbes. This form of defense ensures that bacteria do not grow in the wort, thus ruining the beer with off flavors. However recently with the boom of craft beer different bacteria have been purposefully added to create what is known as sour beer. The sour taste comes from the waste products of the bacteria10.

Conclusion

Saccharomyces cerevisiae has evolved with humans for many thousands of years. It has instrumental in making foods like bread and beer that have become staples of our diets. It has also been essential in biological research to discover multiple proteins that have homologs in humans and other cell processes like cell division, DNA replication, and different metabolisms. Without Saccharomyces cerevisiae research like sequencing complete genomes of eukaryotes would have taken longer and set back science as a whole. Today it has become important in different ways specifically in the production of ethanol as a biofuel. Perhaps Saccharomyces cerevisiae is the future answer to our fossil fuel problem. Only time will tell how much more we learn from this seemingly simple organism.

References

1 Goffeau, A. et al. Life with 6000 Genes. doi:10.1126/science.274.5287.546 (1996).

2 LEGRAS, J.-L., MERDINOGLU, D., CORNUET, J.-M. & KARST, F. Bread, beer and wine:Saccharomyces cerevisiae diversity reflects human history. Molecular Ecology 16, 2091–2102 (2007).

3 McGovern, P. E. et al. Fermented beverages of pre- and proto-historic China. doi:10.1073/pnas.0407921102 (2004).

4 Priest, G. F. & Stewart, G. G. Handbook of Brewing, Second Edition. 84-95 (CRC press, 2006).

5 Cabib, E. Carbohydrates as structural constituents of yeast cell wall and septum. Pure & Appl. Chem 63, 483-489 (1991).

6 Herskowitz, I. Life cycle of the budding yeast Saccharomyces cerevisiae. Microbiol Rev 52, 536-553 (1988).

7 Aquilla, T. The Biochemistry of Yeast | MoreBeer, <http://www.morebeer.com/articles/how_yeast_use_oxygen> (2015).

8 Goldammer, T. The Brewer's Handbook: The Complete Guide to Brewing Beer, <http://www.beer-brewing.com/> (October 2008).

9 Dyda, F. et al. Catalytic centers in the thiamin diphosphate dependent enzyme pyruvate decarboxylase at 2.4-.ANG. resolution. doi:10.1021/bi00075a008 (2002).

10 Fleet, G. 217-262 (Microbiology of Fermented Foods, 2nd ed, 1997).