Methanogenic Anaerobic Digestion of Wastewater

In the present day and age, there is a large emphasis on green technology and environmental sustainability. For sustainability to be achieved, the amount of pollution generated must be reduced, and society must become less dependent on fossil fuels as its main source of energy.1 These two goals can be achieved concurrently via the treatment of wastewater. Wastewaters contain high concentrations of degradable organic material which, when processed, produce valuable bioenergy or biochemicals.1 Wastewater treatment methods vary, but include:

Methanogenic Anaerobic Digestion

Digestion of organic matter in wastewater by methanogenic anaerobic methods is popular because it has “high organic removal rates, low energy-input requirements, energy production, and low sludge production.”1 The conversion of organic material present in wastewater to methane follows a four-step process. First, fermentative bacteria hydrolyze complex organic polymers, such as proteins, polysaccharides, and lipids, to amino acids, sugars, and fatty acids. These monomers are then fermented to intermediates containing a mix of organic alcohols and acids. Acetogenesis further oxidizes the intermediates to acetic acid, hydrogen, and carbon dioxide via hydrogen-producing acetogenic bacteria. More acetate is produced by acetogens and homoacetogens using the hydrogen and carbon dioxide produced in the previous step. Lastly, methanogenesis uses acetoclastic methanogens to convert acetate into methane and carbon dioxide.1

Methane produced from anaerobic digestion is most often used as an on-site fuel source for heating or electricity production using fuel cells, making it a "net positive energy" processes.1 Additionally, by converting it to methanol, methane can be used in the production of biodiesel.2

Three key technologies that utilize methanogenic anaerobic digestion are the upflow anaerobic sludge blanket reactor, anaerobic migrating blanket reactor, and anaerobic sequencing batch reactor.

Upflow Anaerobic Sludge Blanket (UASB) Reactor

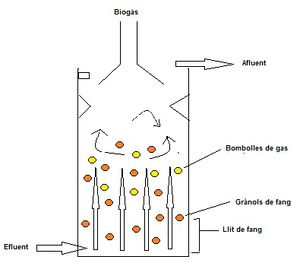

The UASB reactor consists of a single tank, where wastewater enters from the bottom and flows upward into the sludge granules, which filters out organic material, and results in the production of biogas and clarified effluent.3 The sludge blanket is an aggregation of microbes that degrade the organic matter in wastewater, producing methane and carbon dioxide gases in the process. Sludge granules do not mix with the clarified effluent because their weights give them "good settling characteristics,"1 and the reactor has sloped walls to deflect any material that reaches the top.3 Treated water is extracted from the top of the tank.

Advantages of UASBs include low energy requirement, low operation and maintenance costs, low sludge production, resource recovery from biogas production, and high reduction of organic matter.4 It is predicted that the pay back period for UASB technology is less than 3 years.4 UASBs are able to reduce the chemical oxygen demand (COD), a measure of water quality, by 80-90%, thus demonstrating its high organic removal rates.3 Studies have found UASBs to be most effective in the treatment of wastewater from breweries, distellery, pulp and paper, and food processing industries.4

Anaerobic Migrating Blanket Reactor (AMBR)

Anaerobic Sequencing Batch Reactor (ASBR)

References

1. Angenent L., Karim K., Al-Dahhan M., Wrenn B., Domiguez-Espinosa R. (2004). Production of bioenergy and biochemical from industrial and agricultural wastewater. Trends Biot., 22(9): 477-485.

2. Witt, P.M. and Schmidt, L.D. (1996) Effect of flow rate on the partial oxidation of methane and ethane. J catal. 163: 465-475

3. Upflow Anaerobic Sludge Blanket Reactor. Akvopedia.

4. Tare V. and Nema A. UASB technology - expectations and reality. Dept. of Env. Engg., IITT Kanpur, India

Edited by Yenfang Koh, a student of Suzanne Kern in BIOL168L (Microbiology) in The Keck Science Department of the Claremont Colleges Spring 2015.