The Role of Bacteria in the Health Potential of Yogurt

Introduction

At right is a sample image insertion. It works for any image uploaded anywhere to MicrobeWiki. The insertion code consists of:

Double brackets: [[

Filename: PHIL_1181_lores.jpg

Thumbnail status: |thumb|

Pixel size: |300px|

Placement on page: |right|

Legend/credit: Electron micrograph of the Ebola Zaire virus. This was the first photo ever taken of the virus, on 10/13/1976. By Dr. F.A. Murphy, now at U.C. Davis, then at the CDC.

Closed double brackets: ]]

Other examples:

Bold

Italic

Subscript: H2O

Superscript: Fe3+

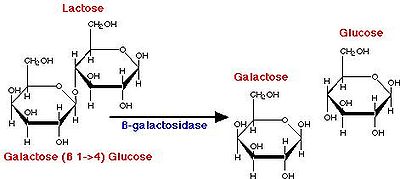

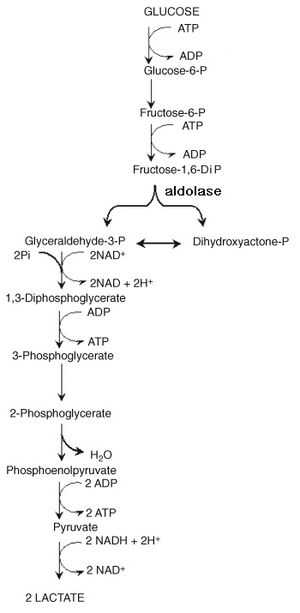

The Biochemistry Behind Yogurt

Introduce the topic of your paper. What microorganisms are of interest? Habitat? Applications for medicine and/or environment?

Yogurt Production

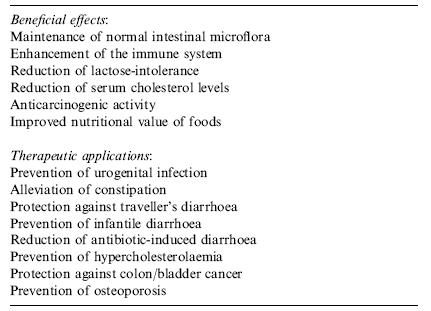

Benefits of Yogurt

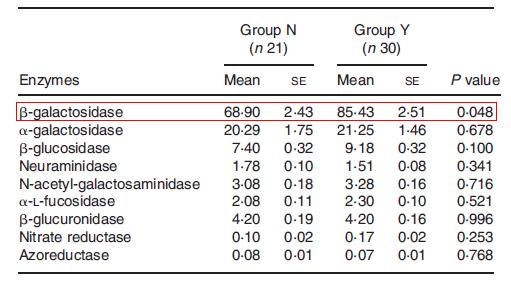

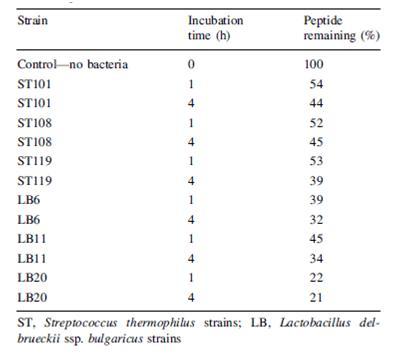

Include some current research, with at least one figure showing data.

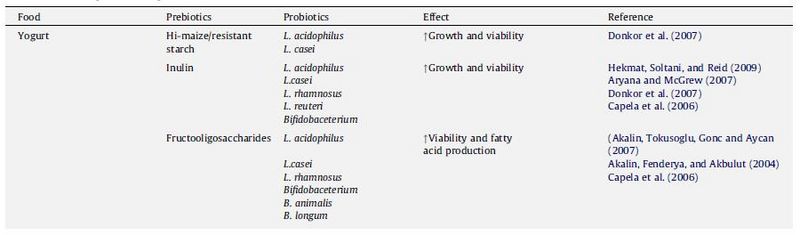

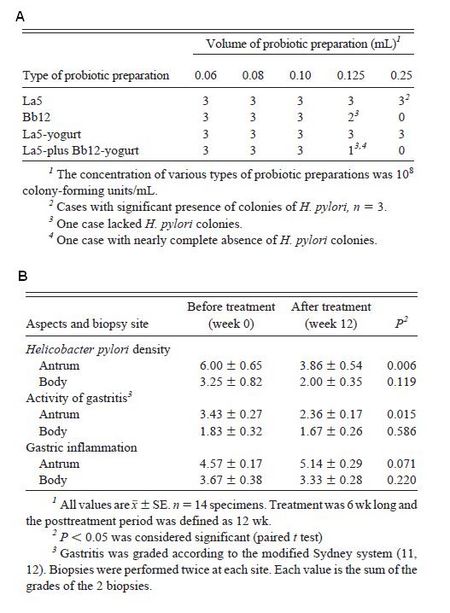

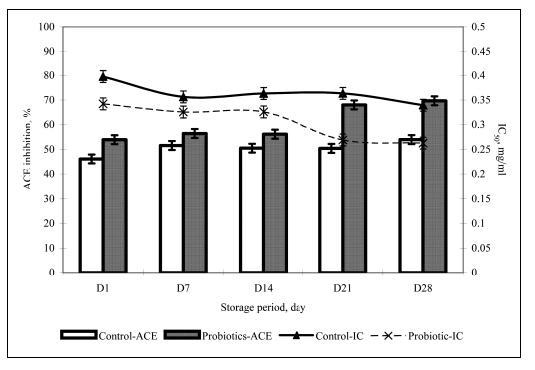

Probiotics

Include some current research, with at least one figure showing data.

Improving Yogurt

Current Problems

Include some current research, with at least one figure showing data.

Improving functionality of Yogurt

Towards a "Superior" Yogurt

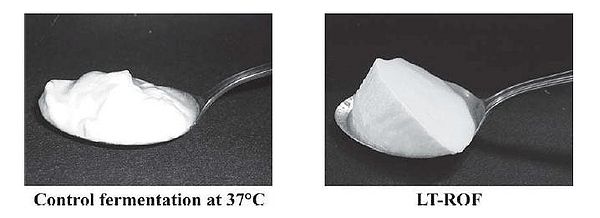

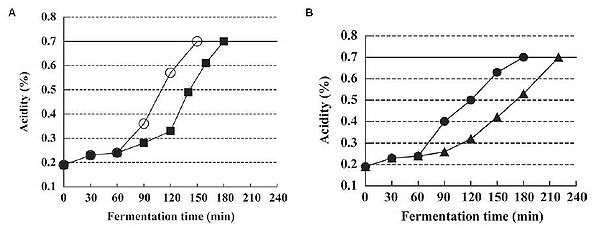

In addition to improving the health potential of yogurt, from an industrial point of view, there is interest in manufacturing a more palatable type of yogurt that appeals to the masses and can be produced efficiently. Such yogurt is generally smooth, mild, and pleasantly sour, though these characteristics may be subject to individual taste. The outcome of yogurt is affected by the quantity and rate of lactic acid addition. L. bulgaricus and S. thermophilus are known to be facultative anaerobic bacteria that can grow in oxygenated environments. It has been found that these species remove the dissolved oxygen in the yogurt mix during fermentation, and only actively begin to produce lactic acid after the dissolved oxygen (DO) concentration in the yogurt mix is lowered to 0 mg/kg (Horiuchi et al., 2009). This suggests that lactic acid production is suppressed by dissolved oxygen in the yogurt mix. By altering the DO concentration to begin with, one could essentially control when lactic acid production begins. In addition to jumpstarting, lactic acid production was also prolonged in a culture that started with 0 mg/kg DO, or reduced dissolved oxygen fermentation (ROF), compared to the control of around 6 mg/kg DO. This means that it takes less time to reach a desired acidity level if yogurt is produced by ROF (Fig. 17A). Moreover, despite initiating lactic acid production much earlier and maintaining it for a longer time, the viable cell counts of the bacterial species and characteristics of the ROF yogurt such as acidity and curd tension were no different from the control yogurt (Horiuchi et al., 2009). One advantage of using ROF is the reduction of production time, as the cultures enter the exponential growth phase sooner. It has been shown that yogurt made at a low temperature produces smooth yogurt and the physical properties of yogurt are improved as the starter culture are given more time to produce aroma substances and other accessory molecules that affect the taste, and are able to block fast acid production (Guzel-Seydim, Sezgin, & Seydim, 2005). Given this fact, Horiuchi et al. (2009) set out to make a yogurt that was smooth but could be counteracted with ROF to reduce the wait time compared to traditional low temperature production, which requires more time in exchange for a smooth product. Using low temperature reduced dissolved oxygen fermentation (LT-ROF), the researchers achieved a "superior" set yogurt with a smooth texture and a strong curd structure. Moreover, the marketability of this type of yogurt production is increased, as Horiuchi et al. (2009) have shown that yogurt produced by LT-ROF takes less time than traditional yogurt produced at 37°C (Fig. 17B), and is comparable to the faster common yogurt production that takes place at 43°C (compare control of Fig. 17A and LT-ROF of Fig. 17B).

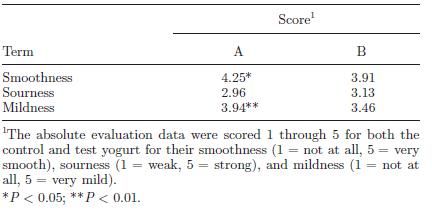

Regardless of the actual percentage of acidity, what is important is how the yogurt appeals to consumers. The LT-ROF yogurt was evaluated to be smoother and milder on average by 200 consumers compared to control yogurt produced at the standard temperature of 43°C (Fig. 18). However, the LT-ROF yogurt turned out to have a smooth texture comparable to the control yogurt made at a lower temperature (37°C). The major difference between these two types of yogurt was the firmness of the curd (Fig. 19). Horiuchi et al. (2009) suggested that having a firm curd was beneficial since manufactured yogurt needs to be transported in trucks, thereby requiring a firmer texture that can withstand the shaking. The researchers thus concluded that the LT-ROW method of producing yogurt was the superior method as it takes about the same time as producing yogurt at 43°C and results in a smooth yogurt that can hold its shape while in transit.

Another study focused on the effect of temperature and starter culture type on the quality of yogurt. Guzel-Seydim, Sezgin, and Seydim (2005) compared how the quality of yogurt changes based on whether it is produced at high (45°C) or low temperatures (35°C) and whether exopolysaccharide-producing or non-producing strains are used. These exopolysaccharides are of interest because it is a ropy, mucoid substance that increases the viscosity of yogurt and decreases whey separation. Guzel-Seydim et al. (2005) quantified the quality of yogurt by looking at the pH, lactic acid percentage, total volatile fatty acids content, acetaldehyde content, tyrosine content, consistency, viscosity, and extent of whey separation of the yogurt samples. They found that the ropy exopolysaccharide-producing strains had a better texture overall when incubated at the lower temperature, but the non-exopolysaccharide strains actually had a better taste, as evaluated by the higher acetaldehyde content. Nonetheless, the researchers suggest that these exopolysaccharide-producing strains may be useful in replacing additives like fat that are used to improve the texture of yogurt. Thus, as is the case with most foods, one would hope to improve not just the taste and texture of yogurt, but also the nutritional value, which also ties back to the health benefits that were described earlier.

Conclusion

Yogurt has a long history and its benefits have been valued by many people, particularly those with gastrointestinal problems. The production behind yogurt is well understood, allowing for improvements and advancements in both the quality and efficient manufacturing of the product. Improving the health potential of yogurt has become a popular field, and for industrial reasons, enhancing the taste and texture, as well as storage life of yogurt is an appealing advancement for yogurt consumers. Yogurt in its basic form is a very eco-friendly product, as humans are essentially consuming the waste products of acidic fermentation. Additionally, the unique taste, texture, and potential for even better health benefits make yogurt an attractive food for people of many cultures.

References

Adolfsson, O., S. N. Meydani, & R. M. Russell. 2004. Yogurt and gut function. Am J Clin Nutr. 80:245–256.

Akalin, A. S., G. Unal., & M. C. Dalay. 2009. Influence of Spirulina platensis biomass on microbiological viability in traditional and probiotic yogurts during refrigerated storage. Ital. J. Food Sci. 21: 356-364.

Akalin, A. S., S. Gonc, G. Unal, & S. Fenderya. 2007. Effects of frutooligosaccharide and whey protein concentrate on the viability of starter culture in reduced-fat probiotic yogurt during storage. Journal of Food Science. 72: M222-M227.

Alvaro, E., C. Andrieux, V. Rochet, L. Rigottier-Gois, P. Lepercq, M. Sutren, P. Galan, Y. Duval, C. Juste, & J. Dore. British Journal of Nutrition. 97: 126–133.

Cornell University Milk Quality Improvement Program. “Yogurt Production.” 29Dec.2006. <http:// www.milkfacts.info/>

Farnworth, E. R., I. Mainville, M.-P. Desjardins, N. Gardner, I. Fliss, & C. Champagne. 2007. Growth of probiotic bacteria and bifidobacteria in a soy yogurt formulation. Journal of Food Microbiology. 116: 174-181.

Gaetke, L.. M., C. J. McClain, C. J. Toleman, and M. A. Stuart. 2010. Yogurt protects against growth retardation in weanling rats fed diets high in phytic acid. Journal of Nutritional Biochemistry. 21: 147-152.

Guarner, F., G. Perdigon, G. Corthier, S. Salminen, B. Koletzkos, & L. Morelli. 2005. Should yoghurt cultures be considered probiotic? Brit. J. or Nutr. 93: 783-786.

Guzel-Seydim, Z. B., E. Sezgin, and A. C. Seydim. 2005. Influences of exopolysaccharide producing cultures on the quality of plain set type yogurt. Food Control. 16: 205-209.

Horiuchi, H., N. Inoue, E. Liu, M. Fukui, Y. Sasaki, and T. Sasaki. 2009. A method or manufacturing superior set yogurt under reduced oxygen conditions. Journal of Dairy Science. 92: 4112-4121.

Kitawaki, R., Y. Nishimura, N. Takagi, M. Iwasaki, K. Tsuzuki, and M. Fukuda. 2009. Effects of Lactobacillus fermented soymilk and soy yogurt on hepatic lipid accumulation in rats fed a cholesterol-free diet. Biosci. Biotchnol. Biochem. 73: 1484-1488.

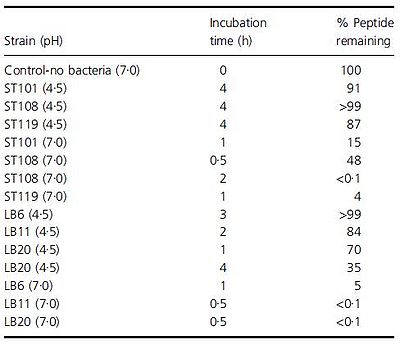

Paul, M. and G. A. Somkuti. 2009. Degradation of milk-based bioactive peptides by yogurt fermentation bacteria. Lett Appl Microbiol. 49:345–350

Paul, M. and G. A. Somkuti. 2010. Hydrolytic breakdown of lactoferricin by lactic acid bacteria. J Ind Microbiol Biotechnol. 37:173–178.

Ramchandran, L. & N. P. Shah. 2008. Effect of Versagel® on the growth and metabolic activities of selected lactic acid bacteria. Journal of Food Science. 73: M21-M26.

Roberfroid, M. B. 2000. Prebiotics and probiotics: are they functional foods? Am J Clin Nutr. 71:1682S–7S.

Schrezenmeir, J. & M. Vrese. 2001. Probiotics, prebiotics, and synbiotics—approaching a definition. Am J Clin Nutr. 73:361S–4S.

Seo, M. H.,S. Y. Lee , Y. H. Chang, & H. S. Kwak. 2009. Physicochemical, microbial, and sensory properties of yogurt supplemented with nanopowdered chitosan during storage. J. Dairy Sci. 92: 5907-5916.

Shah, N. P. 2000. Probiotic bacteria: Selective enumeration and survival in dairy foods. J. Dairy Sci. 83:894-907.

Slonczewski, J.L. and J.W. Foster. Microbiology: An Evolving Science. New York. W.W. Norton & Company, Inc., 2009. Pp. 595.

Vasiljevic, T., T. Kealy, & V. K. Mishra. 2007. Effects of β-glucan addition to a probiotic containing yogurt. J. Food Sci. 72: C405-411.

Wang, K.-Y., S.-N. Li, C.-S. Liu, D.-S. Perng, Y.-C. Su, D.-C. Wu, C.-M. Jan, C.-H Lai, T.-N. Wang, & W.-M.

Wang. 2004. Effects of ingesting Lactobacillus- and Bifidobacterium-containing yogurt in subjects with colonized Helicobacter pylori. Am J Clin Nutr. 80: 737-741.

Wollowski, I. S.-T. Ji, A. T. Bakalinsky, C. Neudecker, & B. L. Pool-Zobel. 1999. Bacteria used for the production of yogurt inactivate carcinogens and prevent DNA damage in the colon of rats. J. Nutr. 129: 77–82.

Edited by student of Joan Slonczewski for BIOL 238 Microbiology, 2010, Kenyon College.