Yogurt

Chemical Structure

Yogurt is made from the fermentation of a generic milk mix and forms a gel made up of a network of casein micelles [1]. In this network structure, there are empty spaces that are filled with a liquid phase. This liquid phase, known as whey, is the liquid part of the milk left after fermentation [2]. There are also slightly larger spaces that are occupied by starter bacteria [1]. Trapped starter bacteria and whey within the casein network provide the viscoelastic properties [1].

Starter Cultures

Specific microorganisms, known as starter cultures, are what determine the body, texture, and flavour of the final yogurt product [4]. These starter cultures initiate every change in the substrate and preserve it by suppressing spoilage and presence of pathogenic flora [4]. They can preserve food through the synthesis of lactic acid and antimicrobial substances [5]. This is because the organic acids not only lower the pH but are also toxic for many microorganisms which are what prolongs the shelf life of the substrate [5]. It is interesting to note that the preservation and creation of new food products such as beer, wine, cheese, bread and sausages has been widely used long before the discovery of microorganisms [5].

Because of the starter cultures impact on creating specific products, only fermentation by the two species Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus produce yogurt [5]. Fermentation of milk by any other cultures results in a different dairy product such as butter or cheese [6]. These two species are lactic acid producing bacteria (LAB) and are gram-positive rods and cocci respectively [5]. They do not form spores and are catalase negative, obligatory fermentative, microaerophilic and non-motile [5]. Isolating the specific starter cultures ‘’L. bulgaricus’’ and ‘’S. thermophilus’’ can be done using differential and selective growth agar mediums [7]. Once the starter cultures have been isolated they can be added into a purified milk sample that is void of antibiotics and contaminants which would cause the product to be different than intended [5].

Classification

Higher order taxa

1. Lactobacillus [8]:

Bacteria; Firmicutes; Bacilli; Lactobacillales; Lactobacillaceae; Lactobacillus

2. Streptococcus thermophilus [9]:

Bacteria; Firmicutes; Cocci; Lactobacillales; Streptococcaceae; Streptococcus; S. salivarius

Introduction of Yogurt Niche

Description of Niche

Yogurt is classified as a dairy product that is made by blending fermented milk with different ingredients that gives flavor and color. The possible origin of yogurt is said to be from Middle East, Turkey or Iran. In 1900, Dr. Ilya Metchnikoff set apart bacillus cultures that were used for making yogurt. In 1925, the first modern yogurt plant was discovered and in 1970s yogurt gained an increasing popularity in United States. In the production of yogurt, cream, milk or skim milk is cultured with two bacteria which are Lactobacillus bulgaricus and Streptococcus thermophilus. Sometimes yogurt is treated with heat after it has been cultured in order to get rid of viable organism and their extended shelf-life. Generally, yogurt is divided into three categories namely, 1) Firm yogurt and it is also called set-style: just as the name implies it is a firm gel in a pack and it is consumed with a spoon, 2) Stirred yogurt: the gel has been dissolved, cooled and packaged after coagulation and 3) Drinkable yogurt: this is similar to stirred yogurt the only difference is that it has been homogenized and reduced to liquid form before filling. The composition of commercial yogurt includes fat which is about 0 to 3.5%, milk solids non-fat (8.25-14%), sugar (0-10%) and stabilizer (0-2%). There are different types of commercial yogurt which are non-fat yogurt, 99% fat free, low fat yogurt and whole milk which is just plain yogurt [10].

Location of microbes

There are two types of bacteria found in yogurt, Lactobacillus bulgaricus and Streptococcus thermophilus. They are also found in the human digestive tract [10].

Physical Conditions

In making of the modern day yogurt, bacterias such as L.acidophilus or a lactose-fermenting yeast is introduced into concentrated sterilized milk and milk solids. The lactose fermenting bacteria are facultative anaerobic, that is they can survive the best in the absence of oxygen while also being able to endure aerobic environments [10]. The product is kept for 4 to 5 hours at 110 – 112 °F (43 – 44 °C) until it forms a cord. Yogurt is mostly stored in the fridge and if frozen it destroys most of the beneficial bacteria.

Microbes Specific to Yogurt

Yogurt Microbial Community

The most common microbial ingredients inside some of your favorite yogurts includes the species Streptococcus salivarius and Lactobacillus delbrueckii. Often these two are both co-cultured with other lactic acid bacteria for health and taste effects. Some of these probiotics include but are not limited to Lactobacillus acidophilus, Lactobacillus casei and Bifidobacterium adolescentis species.

Prescence of Non-microbe

Initially none, but when yogurt is exposed to high temperatures and when there is lack of refrigeration, yeast will grow [11].

Microbial Interactions

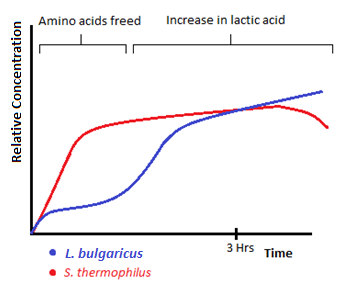

Protocoorperation and antibiosis are the most important interactions in the growth of the yogurt bacteria Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. Protocoorperation can be understood as a mutual beneficial relationship while antibiosis is remarkingly quite the opposite [12]. The associative growth of these two cultures results in a higher lactic acid production and development of flavour than what is possible from a single culture [5]. The rod shaped L. bulgaricus are more proteolytic (metabolically more efficient in the breakdown of proteins) than their symboint counterpart. The S. thermophilus forms acid much slower, especially in milk, which lacks some amino acids. Hence L. bulgaricus liberates small peptides and amino acids, mainly valine, of which serves to enhance the growth of S. thermophilus. In return the cocci enhance the growth of L. bulgaricus by the formation of formic acid from pyruvic acid under anaerobic conditions. Under these protocooperative stimulations during combined growth of the yogurt bacteria, lactic acid is produced at a must faster rate than by that of individual pure cultures. Antibiosis is observed after certain acidity is reached. After this point, growth of S. thermophilus is halted. However, L. bulgaricus are less susceptible to acid and continues to grow [13]. After about 3 hours post incubation, the relative amount of bacteria is equal [14]. The more acid tolerant bacteria, L. bulgaricus, begin to overshadow its counterpart [5]. S. thermophilus is inhibited at pH values between 4.2-4.4, while L. bulgaricus can tolerate pH values as low as 3.5-3.8 [14]. Because of this back and forth growth, to achieve a one to one ratio of these two, the incubation must be done in a controlled manner regulating growth conditions including the concentration of inoculum, time and temperature [5]. Further, once the desired ratio is reached the product should be cooled immediately when finished [5].

Other Niches Affecting Microbes in Yogurt

Influence by Adjacent Communities

The yogurt niche and its environment overlap its similarity between some of the other dairy niches, specifically being the milk niche which is the root of all dairy niches. The making of yogurt is first through the transition of the milk niche. Firstly, yogurt is made from fermented milk. Milk is rich in sugars, more specifically the sugar being lactose. An environment rich in sugars is an environment that microbes love to thrive in; thus, milk is a great feast for microbes. The following are a list of microbes that thrive in milk. Of all the microbes that live in milk, the Bacillus family and the Streptococcus family is the one that overlaps into the yogurt niche. However, there are only two particular microbes that feast in yogurt which are Lactobacillus bulgaricus and Streptococcus thermophilus. So, as we can see there is a similarity between the microbes that thrive in milk to the ones that thrive in yogurt.

Related Microbes in Adjacent Communities

1. Streptococcus lactis [15]

Purpose: Souring

Method: Lactose-lactic acid precipitation

2. Streptococcus bulgaricus [15]

Purpose: Souring

Method: Lactose-lactic acid precipitation

3. Lactobacillus casei [15]

Purpose: Cheese ripening

Method: Controls altermentation.

4. Escherichia coil [15]

Purpose: Souring & gassiness

Method: Lactic acid & gases and affects cheese ripening.

5. Bacillus substallis [15]

Purpose: Protecolysis

Method: flavors change.

6. Streptococcus liquifiecence [15]

Purpose: Bitter Flavour

Method:Bitter flavour to cream &butter.

7. Bacillus substallis [16]

Purpose: Sweet curdling

Method: Curd formation

8. Streptococcus paracitrovorus [16]

Purpose: Attacks citric acid

Method: Flavors curd.

Conditions under which the environment changes

In the process of using the lactose sugar from the milk, Lactobacillus produces acid which makes the yogurt sour and a less suitable place for other microbes. This is why there is a dramatic decrease in the amount of microbes that live in the yogurt niche when compared to the milk niche. Thus the essential conversion between milk to yogurt is the acidic levels. The increase in acidic levels is the sourness that is tasted in yogurt which lacks in milk, another characteristic difference. Lactic acid also known as lactate is not good for bacteria. So, as a response to this change in environment, they excrete lactate into their environment. This again is what causes the pH to fall to become more acidic. Another effect of excreting lactate is that the protein molecules in the milk become denatured. What this means is that the proteins unfold from their normal structures and become disordered. After becoming distorted, the protein molecules begin to stick to each other forming a semi-solid matrix. Thus, this is what gives the yogurt a semi-solid state, another characteristic different from the liquid-milk.

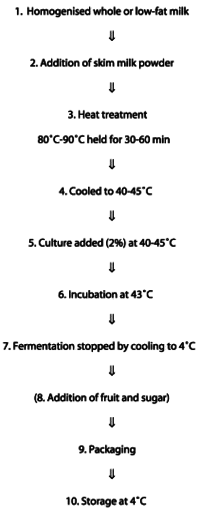

Manufacturing Process of Yogurt

Back-Slopping

The culture added can be isolated using growth plates or taken from a previous batch, called back-slopping [5]. Commercially, the primary method of starting fermentation is back-slopping because not only are there are a greater initial number of desired microorganisms which ensures faster fermentation, but it also allows for a more reliable product [5]. This process also favours the growth of bacteria who release antimicrobial substances ensuring the growth of the same species while reducing the likelihood of another species growing and affecting the final product [5].

Mechanism & Result of Fermentation

Because the starter cultures used have very good acidification activity, the primary result of the fermentation of lactose is the generation of lactic acid and therefore, pH lowers [4]. ‘’S. thermophilus’’ synthesize urease which produces ammonia from the urea in milk which helps counter this acid effect [5]. Despite the production of ammonia, the pH drops below the isoelectic point of casein, a phosphoprotein found in mammalian milk, and the acid casein precipitates forming a solid which has a mild acidic flavour [4]. In recent years, cross linking of casein by transglutaminase is utilized for the fermentation of milk and it modifies casein and whey protein by provoking a mesh-like reduction in the protein structure which increases gel strength [17]. In conjunction with the caseinnetwork, exopolysaccharides are produced by the lactic acid bacteria and are a natural way for the yogurt to be thickened [18].

Microbe Metabolism and its effect on environment and human body

Lactobacillus

Lactobacillus is found to be living in highly acidic environments of pH 4-5 or lower, thereby altering the pH and suppressing pathogens by producing lactic acid [8]. Under the optimal temperature of 37°C, it derives the energy, such as ATP, by converting the glucose to lactic acid through homolactic fermentation. Nevertheless, it is unable to breakdown complex sugars, like ribose, under the optimal temperature [5]. In addition, Lactobacillus secretes nonbacteriocin antibacterial substances. In humans, Lactobacillus is found in the gut and vagina. In the vagina, it plays an important role by keeping the pH low to deter infection.

Streptococcus thermophilus

Under the optimal temperature of 42°C, Streptococcus thermophilus, can generate ATP through fermentation [19]. In contrast to Lactobacillus, it is also able to produce ATP through aerobic respiration in the presence of oxygen. Through fermentation, it converts lactose to lactic acid at the optimal pH of 4.6 [19]. In humans, [Streptococcus thermophilus] is found in the upper part of the intestine and can help people with lactase-deficiency to digest lactose due to the low level of lactase they produce.

Probiotic

Probiotics that are specific to genus Lactobascillus are found in foods and also food supplements [20]. It is the most common bacteria that are classified as a probiotic as it is considered to be “friendly” bacteria. While inhabiting in the intestine and the vagina, the purpose of this friendly microbe is to prevent other "bad" microbes which cause disease. This is done by proliferating at the intestine. Thus, the Lactobascillus microbe acts as a defense system. This is accomplished through a variety of mechanisms. For example, the breakdown of food by Lactobascillus acidophilus leads to production of lactic acid, hydrogen peroxide, and other byproducts that makes the environment hostile for undesired organisms. Other probiotic responses include improving lactose absorption digestion in people who are lactose intolerant, enhancing the immune response, alleviating symptoms of the bowel syndrome [21]. It is also involved in the competitive prevention of pathogens by outcompeting potential pathogens for attachment sites and nutrients. It helps with folic acid and B-vitamin synthesis and it enhances the mineral bioavailability. Just as probiotics has its advantages it also has its disadvantages. Some disadvantages include the viability in product which is a result of species variability [10].

Current Research

Milk fermented with yogurt cultures and Lactobacillus casei compared with yogurt and gelled milk: influence on intestinal microflora in healthy infants [22].

Consuming fermented dairy products have profound health effects, such as providing the minerals and vitamins to humans. They regulate the equilibrium and metabolism of microflora in healthy infants. The experiment was based on comparing the effects of consumption of regular yogurt, milk fermented with yogurt cultures and Lactobacillus casei (YC), and nonfermented gelled milk on the fecal microflora of healthy infants who were divided in three groups, and each group received one of three products. The results show indexes, such as anaerobes, bifidobacteria, bacteroides were not modified during supplementation period. However, in the yogurt group, the number of Enterococci in fecal samples had increased. In the YC group, the number of fecal Lactobacillus had increased in the colon where Lactobacillus may provide physiological benefits. This may prove that Lactobacillus can be used for preventing infectious diseases and stimulating the immune system.

Lactobacillus species properties and Lactose intolerance [23].

This paper talks about the experiments done to test the isolated Lactobacilli from the stomachs of piglets that were related to the properties of fermented milk. Lactobacillus was extracted from piglets because it is likely that there is a high concentration of Lactobacilli. This was specifically directed to the lactose- intolerant humans. There were several properties that were tested for. It was tested for the pH of the fermented milk over a span of 30 days, the reduction of the concentration of the lactose in milk, the viability, and the b-galactosidase activity. Optimal pH levels and ability to grow in an environment of bile salts were determined. Finally, commercial yogurt was also test to products varied in characteristics. The results were found that the Lactobacillus sp. isolated from pigs had lower b-galactosidase activity than did Lactobacillus delbrueckii. Also, the optimal temperature was found to be 4 degrees Celsius for the b- galactosidase activity of the fermented milk to decrease with a lactose concentration of 4% and an active pH of 5.5. Lastly, when comparing the Lactobacilllus bacteria found in the piglet’s stomach to that found in yogurt, it has been proposed that for lactose-intolerant subjects, improved fermented milk products could result by using strains of this bacterium that possess high b galactosidase activity at acidic pH. And thus, these microbial cells that are more resistant to gastric digestion.

Contribution of Streptococcus thermophilus to Growth-Stimulating Effect of Yogurt on Rats [13].

Yogurt is produced by lactic acid fermentation of milk by L. bulgaricus and S. thermophilus. Both L. bulgaricus and S. thermophilus exhibited a protocoorperation association to produce lactic acid at a greater rate. Symbiotically growing, L. bulgaricus provides S. thermophilus with formic acid, which provides better growth, while S. thermophilus releases amino acids, mainly valine to accelerate L. bulgaricus growth. A study was done in rats to identify the source of contribution to growth-stimulating effect in yogurt containing both active lactic acid bacteria L. bulgaricus and S. thermophilus. The test variables were consisted of milk, yogurt, milk fermented individually by L. bulgaricus and S. thermophilus, and milk which both cultures has been added. Rats also fed on diets containing cell fractions, cell supernatant and sonicated cell. The results, 6 of 7 experiments showed significant weight gain in yogurt, and milk fermented by S. thermophilus and milk plus S. thermophilus cells. Because rats fed diets of L. bulgaricus alone did not stimulate any growth, this is hard evidence supporting the sole responsibility and role in stimulating growth in rats.

Antibiotic Resistances of Yogurt Starter Cultures Streptococcus thermophilus and Lactobacillus bulgaricus [24].

A large number of antibiotics are utilized in the dairy industry which in turn is used for mastitis therapy. According to Taber's Cyclopedic Medical Dictionary, mastitis is defined as inflammation of the breast. Also, efforts have been made to grow antibiotic-resistant cultures of lactobacilli in order to use it for the production of yogurt. However, yogurt as we know have very high concentrations of viable microorganisms and due to the uneasiness expressed in recent years about the inessential use of antibiotic-resistant strains, it was considered appropriate to study the resistances of cultures used for yogurt production. In this experiment, twenty-nine strains of Lactobacillus bulgaricus and fifteen Streptococcus thermophilus were screened for the resistance to 35 antimicrobial agents. They used sensitivity disks that were commercially available. In their results they found that 35% of the isolates exhibited unusual resistance patterns. Furthermore, the results obtained from this experiment revealed that certain strains, which would have been used for the production of yogurt under other circumstances, may have lots of inessential antibiotic resistances. Consequently, fewer strains that are resistant to fewer antibiotics have been advised to be used for the production of yogurt in order to minimize the unnecessary dispersion of antibiotic-resistant strains. In addition, out of all the strains used for this experiment some strains has been listed as not expedient for the production of yogurt which are Streptococcus thermophilus strains YS-1, YS-2, YS-3,YS-5, YS-6 and YS-7 and Lactobacillus bulgaricus strains YL-8, YL-10, YL-13, YL-17, LB-3, LB-7, LB-8, LB-9, LB-10, LB-11 and LB-12.

References

(1.) De Vuyst, L., and B. Degeest. 1999. Heteropolysaccharides from lactic acid bacteria. FEMS Microbiol. Rev. 23:153-177. doi: 10.1016/S0168-6445(98)00042-4.

(2.) Sharon Gerdes. 2006. Add Whey to Yogurts and Smoothies. Dairy Foods. 107:66.

(3.) Lee, W. J., and J. A. Lucey. 2004. Structure and Physical Properties of Yogurt Gels: Effect of Inoculation Rate and Incubation Temperature. J. Dairy Sci. 87:3153-3164. doi: 10.3168/jds.S0022-0302(04)73450-5.

(4.) Chandan, R. C., A. Kilara, and Wiley-Blackwell Online Books. 2013. Manufacturing yogurt and fermented milks. Wiley-Blackwell, Chichester, West Sussex.

(5.) Hui, Y. H., and FOODnetBASE. 2004. Handbook of food and beverage fermentation technology. Marcel Dekker, New York.

(6.) Leroy, F., and L. De Vuyst. 2004. Lactic acid bacteria as functional starter cultures for the food fermentation industry. Trends Food Sci. Technol. 15:67-78. doi: 10.1016/j.tifs.2003.09.004.

(7.) Ashraf, R., and N. P. Shah. 2011. Selective and differential enumerations of Lactobacillus delbrueckii subsp. bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, Lactobacillus casei and Bifidobacterium spp. in yoghurt — A review. Int. J. Food Microbiol. 149:194-208. doi: 10.1016/j.ijfoodmicro.2011.07.008.

(10.) Robert Roberts. "History of Yogurt". Associate Professor of Food Science, March 14 2001

(14.) Lourens-Hattingh, A., and B. C. Viljoen. 2001. Yogurt as probiotic carrier food. Int. Dairy J. 11:1-17. doi: 10.1016/S0958-6946(01)00036-X.

(16.)Douglas Goff. "Dairy Science and Technology". University of Guelph 1995

(17.) Beermann, C., and J. Hartung. 2012. Current enzymatic milk fermentation procedures. European Food Research and Technology. 235:1-12. doi: 10.1007/s00217-012-1733-8.

(18.) Aslim, B., Z. Yuksekdag, Y. Beyatli, and N. Mercan. 2005. Exopolysaccharide production by Lactobacillus delbruckii subsp bulgaricus and Streptococcus thermophilus strains under different growth conditions. World J. Microbiol. Biotechnol. 21:673-677. doi: 10.1007/sl1274-004-3613-2.

(20.)Dick Crill. "Growing Microbes". NutriNexusTM 2005

(23.)[http://jds.fass.org/cgi/reprint/80/10/2318 J. P. BURTON and G. W. TANNOCK. "Properties of Porcine and Yogurt Lactobacilli in Relation to Lactose Intolerance". Journal of Dairy Science Vol. 80, No. 10, 1997]

Edited by [Chung Abbott, Ibukun Osindele, Anusha Sridharan, Jerry Wang], students of Rachel Larsen